Frequently Asked Questions

D.I.D Chain number means size. Drive chain also knows as “roller chain” originates in England, this technology has developed and measured by the “Inch” in United States.

D.I.D chains have excellent durability for all range of Motorcycle

- Wear Resistance- it means that the chain retains low friction and increase overall durability against elongation when operating.

- Fatigue Strength- continuous load capacity when the chain is damaged affected on the drive D.I.D chain use selected Hi-carbon steel, special heat treatment and made by high- technology process

- Tensile Strength- tensile strength is breakage load capacity when the chain is damaged affected by maximum torque when driving starts.

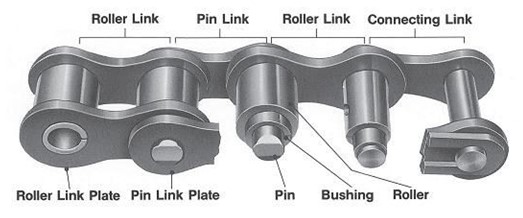

Pin- support all the load acting on the chain, together with the inner and outer plate, and when the chain is engaged with a sprocket, the pin slides as bearings.

Bushing- act to prevent the shock received through rollers when the chain is engaged with sprocket from being directly transmitted to pins, and also act as bearing along with the pins.

Roller- act to smoothly bend the chain when the chain is engaged with a sprocket to protect the chain from impact with the sprocket.

Inner/ Outer plate- plates are subject to repeated tension of the chain and sometimes a large shock.

Seal Ring- acts to seal the grease on parts of pin and Bushing area prevents wear elongation.

Grease- Lubricant parts of pin and Bushing area for low friction

Because of our world class products and truly reliable quality of works, D.I.D motorcycle chain have been used by World Top Riders in many categories- MotoGP, AMA Super Sports, AMA Formula, AMA Superstock, AMA Motocross, & AMA Supercross

PROBLEM | CAUSED BY | MAINTENANCE/ SOLUTION |

1. Improper Lubrication | 1. Lubrication and Maintenance must be done on 500km/ride | |

1. Excessive wear elongation of chain | 1. Replace an exclusively worn chain | |

1. Chain too lose | 1. Pay constant attention to the chain sag, correct by adjusting it according to the procedure stated in motorcycle instruction manual | |

1. Incorrect Alignment of Sprockets | 1. Check the chain adjuster on motorcycle to avoid shortening of chain life due to abnormal wear of sides of the link plate caused by misalignment | |

1. Load in excess of tolerance | 1. Replace with new ones by checking your motorcycle instruction manual | |

Excessive tension and Riding of chain over sprocket and corrosion of chain and Improper lubrication | Replace it with new ones by checking your motorcycle instruction manual | |

1. Fatigue Fracture | 1. Fatigue fracture of plates & bending fatigue fracture is caused by a chain used for a long time at a load exceeding the maximum allowable tension. If the life before fatigue fracture is shorter than the expected life, replace your chain | |

Incorrect alignment of Sprocket | Misalignment of Sprocket result in abnormal wear of sides of link plate, thereby shortening chain life. Check the chain adjuster on your motorcycle |

Problem caused due to insufficient lubrication

- Wear of pins- shorten chain life

- Rough Contact with Sprocket- increase noise

- Stiff Links- Low mileage

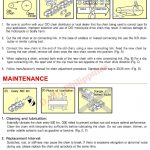

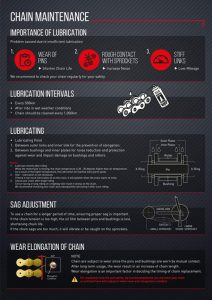

- Every 500km

- After ride in wet weather conditions

- Chain should be cleaned every 1,000km

*Lubricating Point

- Between outer links and inner link for the prevention of elongation

- Between bushings and inner plates for noise reduction and protection against wear and impact damage on bushings and rollers.

Notes:

- Lubricate shortly after riding

While the motorcycle is moving, the chain temperature is 20-30 degrees higher than air temperature. As a result of the higher temperature, the lubrication oil reaches every parts easily. - Over-lubrication is not necessary

If there is too much lubrication oil on the chain, it will splatter when the chain starts to move. - Check your chain after tough riding

Circuit racing or long riding on a highway will result in stress on the chain

We recommend checking your chain and subsequently lubricating it after such riding.

To use a chain for a longer period of time, ensuring proper sag is important. If the chain tension is too high, the oil film between pins and bushings is lost, shortening chain life. If the chain sags are too much, it will vibrate or be caught on the sprockets.

Chain are subject to wear since the pins and bushings are worn by mutual contact. After long term usage, the wear result in an increase of chain length. Wear elongation is an important factor in deciding the timing of chain replacement

FOR A HEALTHIER RIDE, CONSULT YOUR DOCTOR!